I’ve been meaning to provide an update on the Access 65 for awhile now and a recent comment on my previous post just reminded me to do that. Also realizing how many times I tried to find user-specific information on the jig before I bought it, I really want to give out as much info on the details as possible for those thinking of getting this frame fixture.

The first thing I did was make a little seat tube holder from a Pony clip ($4) and a vertical toggle clamp ($12). I pretty much stole this idea (again) from a picture I saw on Garro’s blog (Coconino Cycles) but instead of using a Sputnik braze-on clamp I made this lil thing, which works really well if I do say so myself. Just had to drill two holes into the toggle clamp, find two screws that fit, and done! Maybe a 5 minute job.

The other thing that I learned about the Access 65 is that if you are building bikes with certain dimensions there can be issues. The frame I’m building is a 29er with a 24.5″ effective top tube length and the Access 65 needs some ‘adjustment’ to make this work. You can build bikes with much longer top tubes than this, but there are a few things that aren’t super intuitive until you do them once. The square bars that slide past each other to extend the chainstay length, and the BB to headtube length, hit metal bumpers/spacers that force the bars to stay perfectly horizontal when sliding them back and forth. There are holes in the black plates at certain locations that lock down the sliding bars to the rear aluminum plate with 8mm bolts. Once you hit the bumpers/spacers while extending the bars past each other, you will need to undo the screw/s that tighten the jig together, slide the bars farther so the hole passes the spacer, and then screw it back together. There is a zone in there where the screw cannot pass back through the hole because the spacer gets in the way (the “blind spot” i’ll call it). With a longer top tube, one of the bumpers behind the main “Access 65” plate (see pic below) gets in the way of screw going back in, at least with my frame geometry. This only happens when the steering axis to BB distance is between about 65 and 67.5cm (about…i forgot the exact blind spot). You’ll see from the picture that much longer bikes can be built (once you get past the blind spot) but mine just happened to be in this no-bolt zone.

The other thing that I learned about the Access 65 is that if you are building bikes with certain dimensions there can be issues. The frame I’m building is a 29er with a 24.5″ effective top tube length and the Access 65 needs some ‘adjustment’ to make this work. You can build bikes with much longer top tubes than this, but there are a few things that aren’t super intuitive until you do them once. The square bars that slide past each other to extend the chainstay length, and the BB to headtube length, hit metal bumpers/spacers that force the bars to stay perfectly horizontal when sliding them back and forth. There are holes in the black plates at certain locations that lock down the sliding bars to the rear aluminum plate with 8mm bolts. Once you hit the bumpers/spacers while extending the bars past each other, you will need to undo the screw/s that tighten the jig together, slide the bars farther so the hole passes the spacer, and then screw it back together. There is a zone in there where the screw cannot pass back through the hole because the spacer gets in the way (the “blind spot” i’ll call it). With a longer top tube, one of the bumpers behind the main “Access 65” plate (see pic below) gets in the way of screw going back in, at least with my frame geometry. This only happens when the steering axis to BB distance is between about 65 and 67.5cm (about…i forgot the exact blind spot). You’ll see from the picture that much longer bikes can be built (once you get past the blind spot) but mine just happened to be in this no-bolt zone.

Apparently, I’m the first one that has questioned Hank about this in the 8-year life of this frame fixture which was obviously really surprising to me. He said this will be fixed in the next version of the jig. All it’ll take is drilling and tapping another hole into the black Access65 plate and into the rear aluminum plate about 2-3cm to the right of the hole currently there (there’s a little scratch mark where I’ll do this once this frame is done). I’m sure other people noticed this issue but have just placed a C-clamp in place of the bolt to keep it tight and inline (like I did below). I just thought i was doing something wrong so had to call Hank and see what my novice dumbassity was doing now!

UPDATE: 9/30/2001.

The frame jig has helped me build 6 frames up till now. I still love how simple and relatively light it is and how much access you have to the backside of joints. There are things I would change but overall I’d recommend it. Most of my issues could be seen as “opportunities” to create add-ons to the fixture and be creative and learn in doing so. The first thing I’d love to see added would be some type of chainstay support beam that sandwiches the stays so they don’t fall to the floor dinging the tubes and the nice miters you just spent so much time finishing. This is not a huge deal if you use plate-style dropouts and slot your chainstays, but when you use Breezer/Wright-style dropouts there is nothing but pressure to hold them in there while you tack. I end up having to do a bit of TIG-Twister to hold the chainstay in there with my left hand and putting in a light tack on the bottom bracket/chainstay juntion without using any filler rod. There’s plenty of room to make your own fixture and attach it to the Access 65’s main chainstay bar…but to me it further highlights that this jig was made with building lugged frames in mind. This also holds for the seat stays. The bar that comes with the jig is great for placing the stays against to measure and miter, but with hooded dropouts, they tend to not stay put very well. A tube clamp extension from the main jig would be really nice to have. I have been using an old toe-strap but it only does it’s job half-well and is mostly just for holding it there while you tack.

44mm head tubes:

A really cool thing I found out by accident is that if you want to use a 44mm ID head tube on a frame, the stock head tube cones will not work – they’re too small. I found some “Frame jig centering cones” on eBay, made for motorcycle jigs, that fit PERFECTLY onto the 3/4″ head tube bar of the Hank 65. I mean, perfect. All you have to do is flip the stock cones on the bar, inserted the new bigger moto-sized cones and voila’…pretty easy and cheap fix (they were $35 and they are still up there on a continuous auction if you search).

Setting the frame dimensions: Head tube height:

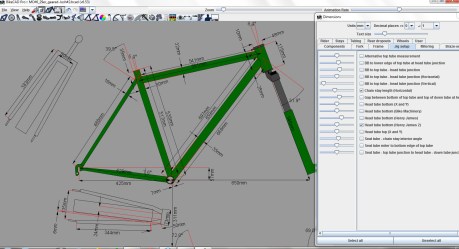

I also wanted to update this post (my most popular post by far since there is very little working info on the Hank 65 online) on how you transfer your BikeCAD or other dimensional drawing to the fixture. BikeCAD, under “Dimenions” and “Jig Setup” tab has a checkbox to show the “Henry James 2” jig setup measurements. There are two major lengths shown – the length from the center of the BB to the centerline of the head tube, and the length from where the BB/HT axis intersection up to the bottom of the head tube (see pic).

The BB to HT axis measurement is integrated into the jig – it’s one of the three square bars that slide horizontally and it’s easy to set. I talked about it above in the first update. But the HT/BB centerline measurement is not integrated into the jig itself but needs to be set with a customruler supplied with the jig. The below pics show how it’s done.

Great post again many thanks.I’m wondering if this is the jig for me!

Firstly thanks again for sharing your experiences with the HJ jig. There is little info out there! I hoped you could share your learnings with locating the lower HT height (in relation to BB) on this fixture. I suppose it’s not marked off on the jig? I’m slowing working up the resources to build again and would like to get it ‘right’ in choosing a fixture. So far this one is in the front running due to low weight, easy access and reasonable cost.

I hope the newest update answers your questions on the HT height measurement, I forgot to mention that before! I still think this is the best jig for the price. I know people build their own but with the time it takes to do that (research, trial/error, parts and labor) i think this is a solid competitor if you were to quantify it (parts + pay yourself to build your own jig). The Anvil’s are just too much money for the hobbyist even though they definitely have a lot of features that I’d love to have!

oh yes thank you thank you for that update and taking the time to show it visually! I always wondered about those out outputs from my copy of bike cad. thanks for demystifying it. Again awesome building.

Hi,

You helped me a while back with some welding questions. It must have worked since I did complete my first TIG welded frame, a 29er that is still stuck together.

Anyhow, I was starting to think about another project and due to the difficulty of finding conventional 1 1/8 steerer forks I was thinking of building a mountain bike around a 44mm i.d. headtube. But, as you found out, it would slip right over my Henry James jig cones.

I see your advice about the motorcycle cones. In my limited searching it doesn’t seem that they are still there on eBay. I see some cones for sale online but the ones I found are for a 3/4″ threaded rod. I was wondering if your cones are of this type or if they have a smooth bore.

Thanks,

Jason

Very cool on the frame, glad I could help out!

For the larger cones, the ones I got on eBay were not threaded. Once I sold my Access jig (with the cones), Joe Bringheli turned a couple cones out for my small alignment table at a reasonable price ($75 i think?). They have a set screw to keep them in place on the 3/4″ rod that fits in the head tube for measuring alignment and coldsetting.

I’m surprised that Hank doesn’t offer something for his jigs yet since it’s the standard head tube size for MTB’s now.

Good luck on the build!